Understanding Potential Failures of BMW N13 Engine and How to Fix Them

Understanding Potential Failures of BMW N13 Engine and How to Fix Them

Blog Article

Exploring the Efficiency and Requirements of the BMW N13 Engine: A Comprehensive Guide

The BMW N13 engine, introduced in 2011, represents a significant improvement in automotive engineering, characterized by its turbocharged inline-four style and advanced innovation. With an ability of 1.6 litres, it stabilizes efficiency and efficiency, offering a significant variety of horsepower and torque suited for different BMW and MINI versions. Recognizing its full potential requires a closer exam of its requirements, capabilities, and the critical duty of maintenance in ensuring optimal efficiency. What understandings can be amassed from a comprehensive analysis of this engine's applications and dependability?

Introduction of the BMW N13 Engine

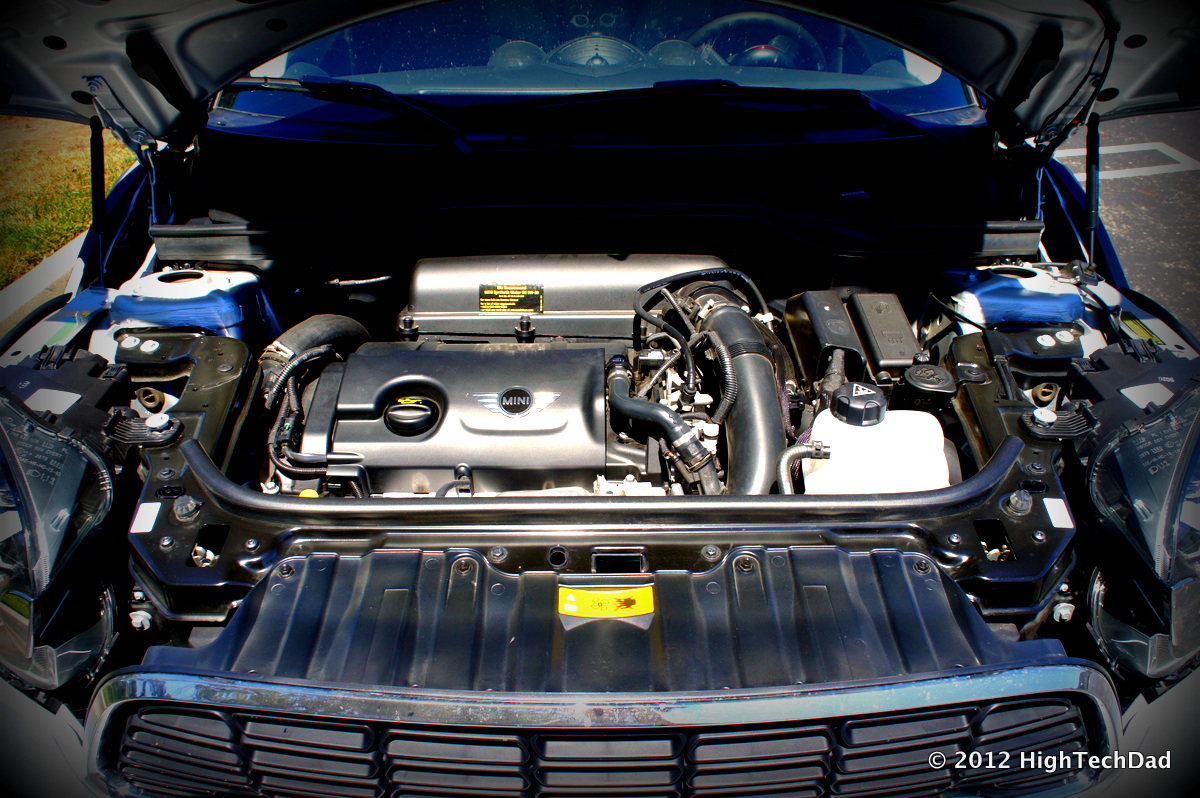

The BMW N13 engine, which debuted in 2011, is a turbocharged inline-four powertrain designed to supply both efficiency and effectiveness. This engine belongs to BMW's modular engine household and was largely presented in the BMW 1 Series and 3 Series versions, to name a few. With a focus on density and weight decrease, the N13 engine integrates innovative engineering methods that boost its total effectiveness.

The N13 engine uses a twin-scroll turbocharger, which enhances airflow and minimizes turbo lag, causing a receptive driving experience. Its straight fuel shot system more adds to improved fuel economic climate and lowered discharges, lining up with modern ecological requirements. The engine features a robust aluminum block and aluminum DOHC cyndrical tube head, which advertises resilience while additionally reducing weight.

In Addition, the N13 is created with a balance of power and effectiveness in mind, giving sufficient horsepower for perky driving without jeopardizing fuel intake. This dual focus makes it an attractive choice for those looking for a vibrant driving experience together with practicality. Generally, the BMW N13 engine stands for an advanced blend of innovation and performance, setting a standard in its class.

Trick Specifications and Attributes

With a focus on efficiency and effectiveness, the BMW N13 engine flaunts excellent requirements that highlight its engineering excellence. This inline-four engine features a displacement of 1.6 litres and uses a turbocharger to enhance power result while preserving gas performance. The N13 engine is configured with a DOHC (Twin Overhead Camshaft) arrangement and employs Valvetronic innovation for variable shutoff timing, adding to optimal performance throughout various driving problems.

Trick specifications include an optimal power output of about 136 horsepower at 4,500 RPM and a peak torque of around 220 Nm readily available from 1,250 to 4,300 RPM. This engine is designed with a lightweight aluminum building and construction, making certain decreased weight and boosted thermal efficiency. Additionally, the N13 engine is compatible with both petrol and bio-fuels, permitting flexibility in fuel alternatives.

The engine is coupled with either a 7-speed dual-clutch or a 6-speed guidebook automatic transmission, allowing smooth gear changes and improving the overall driving experience - BMW N13 Engine. With these vital requirements and functions, the BMW N13 engine exemplifies a mix of efficiency, performance, and modern-day engineering, making it a remarkable option in the vehicle market

Performance Abilities and metrics

The N13 engine includes BMW's Twin Scroll turbocharging innovation, which improves throttle action and reduces turbo lag, supplying a seamless power delivery. Its sophisticated straight fuel injection system optimizes burning efficiency, contributing to improved fuel economic situation and reduced exhausts, critical for meeting contemporary environmental requirements.

Applications in BMW Versions

In the 1 Series, the N13 engine supports designs such as the 114i and 116i, providing perky velocity while maintaining commendable gas economic situation. The engine's receptive turbocharging improves the driving experience, making it appropriate for city commuting and vibrant driving circumstances. In a similar way, in the 3 Collection, the N13 is used in the 316i variant, where it adds to an all-round performance account that straightens with BMW's online reputation for flashy yet functional vehicles.

Past these core versions, the N13 engine has additionally been included in numerous MINI lorries, additionally demonstrating its versatility and performance. The combination of this engine across various platforms highlights BMW's dedication to innovation and performance, guaranteeing that clients obtain a refined driving experience regardless of model selection. This adaptability marks the N13 engine as a substantial element of BMW's design portfolio.

Maintenance and Integrity Insights

Ensuring the long life and efficiency of the BMW N13 engine requires routine upkeep and attention to certain components. Key locations that require regular inspection include the oil and cooling down systems, as these straight influence engine efficiency and overall dependability. Engine oil must be altered at intervals recommended by BMW, normally every 10,000 to 15,000 kilometers, making use of top quality artificial oils to safeguard versus wear and down payments.

The N13 engine is also recognized for its turbocharged setup, which requires careful surveillance of the turbocharger's health. Regular look for increase leakages and wastegate feature can protect against prospective failings. In addition, the timing chain ought to be checked occasionally, as it is recognized to experience wear over time, which can bring about severe engine damages otherwise addressed promptly.

Furthermore, digital parts and sensing units should not be ignored; routine diagnostics can help in identifying any kind of issues before they escalate. Following a structured maintenance routine and making use of OEM components for replacements will considerably boost the engine's reliability, guaranteeing that it remains a durable entertainer throughout its lifespan. Eventually, persistance in maintenance will not just promote performance yet likewise lengthen the engine's operational life.

Final Thought

In verdict, the BMW N13 engine exemplifies innovative engineering with its turbocharged inline-four setup, supplying a blend of power and effectiveness. Normal upkeep is imperative for sustaining the engine's efficiency and long life, guaranteeing it continues to be an affordable option in the automotive market.

The BMW N13 engine, which debuted in 2011, is a turbocharged inline-four powertrain developed to provide both efficiency and effectiveness.With a focus on performance and efficiency, the BMW N13 engine flaunts impressive specs that highlight its design quality.Building upon the remarkable requirements described, the performance address metrics and capabilities of the BMW N13 engine even more illustrate its strengths in real-world applications. Generally, the BMW N13 engine showcases a compelling mix of efficiency and performance, making it a significant competitor in the small engine segment.

Making certain the durability and efficiency of the BMW browse this site N13 engine needs regular upkeep and attention to particular parts.

Report this page